社名 Company Name |

株式会社 東鋼 TOKO CO., LTD. |

代表者 President & CEO |

代表取締役社長 寺島 誠人 Makoto TERASHIMA |

創業 Established |

昭和12(1937)年 1940 |

設立 Incorporation |

昭和29(1954)年1月16日 January 16, 1954 |

資本金 Capital Stock |

62,868,500円 62,868,500 yen |

住所 Headquarters |

〒113-0033 東京都文京区本郷5-27-10 〒113-0033 5-27-10 Hongo, Bunkyo-ku, Tokyo |

| TEL | 03-3815-5811 81-3-3815-5811 |

| FAX | 03-3815-5911 81-3-3815-5911 |

関連サイト related sites |

|

加入団体 membership groups |

日本機械工具工業会 切削フォーラム21 Japan Cutting & Wear-resistant Tool Association Cutting Tools Forum 21 |

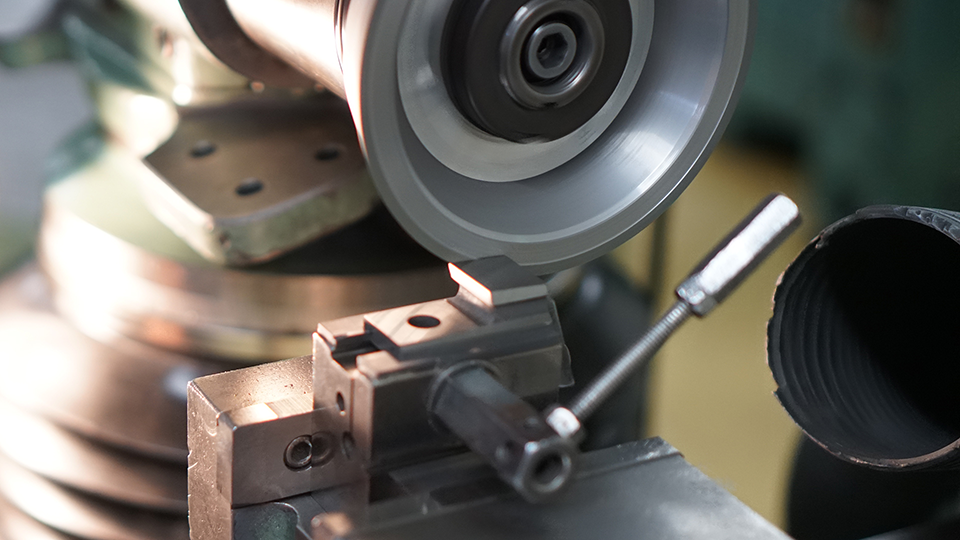

| 1937 | 寺島禮三が寺島商工を創業し、完成バイトの販売を開始 Reizo Terashima founded Terashima of Commerce/Industry and started selling Tool Bits. |

| 1945 | 終戦と共に一時中断 Terashima of Commerce/Industry was temporarily suspended with the end of the war. |

| 1949 | 東鋼製作所を創立し、完成バイトの販売を再開 TOKO Factory was established and resumed sales of Tool Bits. |

| 1954 | 従来の個人企業から資本金125万円で株式会社東鋼を設立 TOKO CO.,LTD. was established with capital of 1.25 million yen from a sole proprietor. |

| 1964 | 茨城県開発公社の誘致企業として猿島郡五霞村に茨城工場を建設操業開始 Ibaraki Factory was built in Goka-mura, Sashima-gun as a company attracted by the Ibaraki Prefectural Development Corporation, and started operations. |

| 1974 | 名古屋営業所設立 Nagoya Sales Office was established. |

| 1980 | 本社社屋竣工 Headquarters Building was completed. |

| 1991 | 福島県石川郡石川町に福島工場を建設操業開始 Fukushima Factory was built in Ishikawa-cho, Ishikawa-gun, Fukushima Prefecture and started operations. |

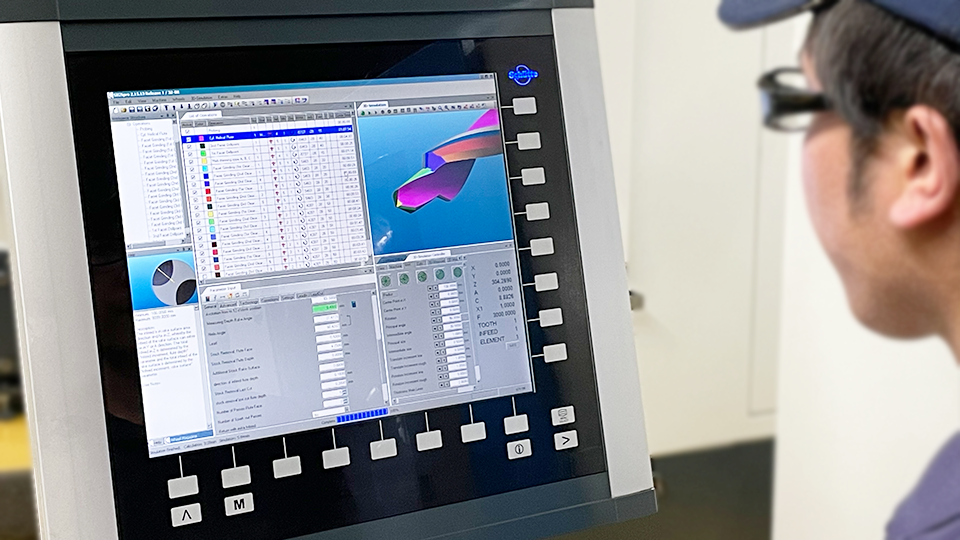

| 2006 | 福島工場第二期工事医療機器分野への参入 Fukushima Factory started the second phase construction and entered into the business field of medical devices. |

| 2009 | 茨城工場、福島工場、医療機器製造業許可(一般医療機器)を取得 Ibaraki and Fukushima Factories obtained a license for manufacturing of general medical devices . |

| 2011 | MEDICA初出展 TOKO CO.,LTD. exhibited for the first time at MEDICA. |

| 2012 | 名古屋営業所移転、神戸営業所新設、東北営業所開設 Nagoya Sales Office was relocated, Kobe Sales Office was established, Tohoku Sales Office was established. |

| 2013 | 茨城工場を閉鎖し福島工場に統合 ISO013485取得 Ibaraki Factory was terminated and integrated into Fukushima Factory, acquiring ISO013485. |

| 2014 | 第三種医療機器製造販売業許可取得 Fukushima Factory obtained the third-class marketing license for medical devices. |

| 2016 | 福島工場第三期工事(事務所棟、研修・厚生棟建設) Fukushima Factory started the third phase construction (Construction of office building, training / welfare building) |

| 2019 | 第二種医療機器製造販売業許可取得 Fukushima Factory obtained the second-class marketing license for medical devices. |

| 2021 | 名古屋オフィス、神戸オフィス閉鎖 Nagoya office and Kobe office close. |

こちらは、医療従事者を対象に製品等の提供をする事を目的としたサイトです。

一般の方に対する情報提供を目的としたものではありませんので、ご了承ください。

This site is intended to provide healthcare professionals with information about our products. Please note that it is not intended to provide information to the general public.